Restaurant Hood Suppression Systems: Essential Fire Safety in Commercial Kitchens

Restaurant hood suppression systems are a critical component of fire safety in commercial kitchens, where the risk of fire is significantly higher due to the presence of cooking equipment, open flames, and flammable oils and greases. These systems are designed to detect and suppress fires that originate in cooking areas, particularly in and around the kitchen hood, which is one of the most vulnerable spots in a restaurant. This article delves into the importance, operation, types, and maintenance of restaurant hood suppression systems, as well as the regulations governing their installation and use.

What is a Restaurant Hood Suppression System?

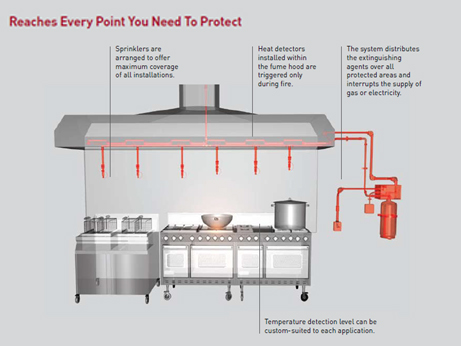

A restaurant hood suppression system, also known as a kitchen fire suppression system, is an automatic fire protection system specifically designed to extinguish fires in commercial kitchens. These systems are installed within the kitchen hood and ductwork, where they can effectively detect and suppress fires before they spread to other parts of the restaurant.

The primary function of a hood suppression system is to protect the cooking appliances, ventilation system, and surrounding areas from fire by quickly detecting and extinguishing any flames. The system is typically linked to the cooking equipment, so it can automatically shut off gas and electricity to prevent the fire from spreading or reigniting.

How Does a Restaurant Hood Suppression System Work?

Restaurant hood suppression systems operate through a combination of detection, suppression, and automatic shutdown mechanisms. Here’s how they work:

1. Fire Detection: The system is equipped with heat detectors, typically fusible links, or thermal sensors, that are strategically placed within the hood and ductwork. When these detectors sense a high temperature indicative of a fire (usually around 280-360°F or 140-182°C), they trigger the suppression system.

2. Automatic Activation: Once the system is activated, it automatically releases the fire suppression agent. This agent is typically a wet chemical that is designed to combat grease fires. The agent is stored in pressurized tanks connected to a piping network that leads to nozzles positioned above the cooking appliances and within the hood.

3. Suppression Agent Discharge: The wet chemical agent is discharged through the nozzles directly onto the fire. When the agent comes into contact with the burning grease or oil, it creates a soapy foam layer that cools the flames, cuts off the oxygen supply, and prevents the fire from spreading. This process is known as saponification, which effectively smothers the fire.

4. Automatic Equipment Shutdown: Simultaneously, the system automatically shuts down the fuel supply and electrical power to the cooking appliances. This step is crucial in preventing re-ignition after the fire has been suppressed.

5. Ventilation Shutdown: In some systems, the ventilation fans within the hood may also be shut down to prevent the fire from spreading through the ductwork. This helps contain the fire and smoke, protecting other parts of the building.

6. Alarm Activation: The system typically includes an alarm component that alerts kitchen staff and other occupants of the fire. In some cases, the alarm may also be connected to the building’s fire alarm system, notifying the fire department and triggering an evacuation if necessary.

Types of Suppression Agents Used in Hood Systems

The most common suppression agent used in restaurant hood suppression systems is a wet chemical agent. This agent is specifically formulated to combat Class K fires, which involve cooking oils and fats. Here's a closer look at the types of agents used:

1. Wet Chemical Agents: Wet chemical agents are the most effective for grease fires. They consist of potassium-based solutions that, when discharged, create a chemical reaction with the hot grease to form a thick, soapy foam. This foam covers the burning material, cutting off the oxygen supply and cooling the area to prevent re-ignition.

2. Dry Chemical Agents: While less common in modern systems, some older kitchen suppression systems may use dry chemical agents like sodium bicarbonate or monoammonium phosphate. These agents work by interrupting the chemical reaction of the fire. However, they are not as effective as wet chemicals for grease fires and may leave a residue that is harder to clean.

3. Water Mist Systems: In some cases, water mist systems can be integrated with hood suppression systems. Water mist uses fine droplets of water to cool the fire and reduce the temperature quickly. However, they are typically used in conjunction with other agents since water alone is not effective for grease fires.

Importance of Restaurant Hood Suppression Systems

1. Fire Safety Compliance: Fire codes and regulations in most regions require the installation of hood suppression systems in commercial kitchens. Compliance with these regulations is not only mandatory but also crucial for the safety of the establishment.

2. Protection of Life and Property: The primary purpose of a hood suppression system is to protect lives and property. Fires in commercial kitchens can spread rapidly, endangering both staff and customers. A well-maintained suppression system can contain and extinguish a fire before it causes significant damage.

3. Minimizing Downtime: A fire in a commercial kitchen can result in costly downtime while repairs are made and inspections are conducted. By quickly extinguishing a fire, a hood suppression system can minimize damage and allow the restaurant to resume operations more quickly.

4. Insurance and Liability: Many insurance providers require commercial kitchens to have an operational hood suppression system. Failure to comply with this requirement can lead to higher insurance premiums or denial of claims in the event of a fire. Additionally, having a suppression system in place reduces the liability of the restaurant owner in the event of a fire-related incident.

Installation and Maintenance

The installation and maintenance of restaurant hood suppression systems must be carried out by qualified professionals to ensure compliance with fire safety regulations and proper system performance.

1. Installation: The installation of a hood suppression system involves careful planning and design to ensure that all cooking appliances and ventilation systems are adequately protected. The system must be installed according to the manufacturer’s specifications and local fire codes. It typically includes connecting the system to gas and electrical shut-off devices, ensuring proper nozzle placement, and integrating the system with the kitchen’s fire alarm.

2. Regular Maintenance: Regular maintenance and inspections are crucial to ensure the system’s readiness in the event of a fire. Maintenance tasks include:

- Inspecting fusible links or thermal sensors: These should be checked regularly to ensure they are free of grease and debris and are functioning correctly.

- Checking the suppression agent levels: Ensuring that the agent is at the correct pressure and has not expired.

- Testing the system: This includes testing the automatic activation and shutdown functions to ensure they work properly.

- Cleaning: Regular cleaning of the hood, ducts, and nozzles to remove grease buildup, which can impair the system’s effectiveness.

- Replacing parts: Any worn or damaged parts, such as nozzles, hoses, or links, should be replaced promptly.

3. Semi-Annual Inspections: Most fire codes require that hood suppression systems be inspected and tested by certified professionals at least twice a year. These inspections ensure that the system is compliant with current regulations and is functioning as intended.

4. Training: Kitchen staff should be trained on how the hood suppression system operates, what to do if it activates, and how to manually activate the system if necessary. This training is critical for ensuring a prompt and effective response in the event of a fire.

Regulatory Standards

Several standards and regulations govern the installation, maintenance, and operation of restaurant hood suppression systems:

1. NFPA 96: The National Fire Protection Association’s (NFPA) Standard 96 outlines the requirements for the installation, inspection, and maintenance of ventilation control and fire protection of commercial cooking operations. It provides detailed guidance on the design and installation of hood suppression systems, including requirements for system activation, agent discharge, and shutdown of fuel sources.

2. UL 300: UL 300 is a testing standard for commercial kitchen suppression systems. It requires that systems be tested for their ability to extinguish modern, high-temperature cooking oil fires, which are more challenging to extinguish than fires involving older, animal-based fats. Systems that meet UL 300 standards are considered the most effective for protecting commercial kitchens.

3. Local Fire Codes: In addition to national standards, local fire codes may impose additional requirements for hood suppression systems. These can include specific installation guidelines, inspection frequencies, and certification requirements for maintenance personnel.

Challenges and Considerations

While restaurant hood suppression systems are essential for fire safety, there are some challenges and considerations to keep in mind:

1. Grease Buildup: One of the biggest challenges in maintaining an effective hood suppression system is managing grease buildup. Grease can accumulate in the hood, ducts, and suppression nozzles, potentially impairing the system’s effectiveness. Regular cleaning is essential to prevent this.

2. System Activation During Cooking: In some cases, the system may activate accidentally due to excessive heat or smoke from normal cooking operations. While this can cause disruption, it’s often a sign that the system is working correctly. Ensuring proper ventilation and maintaining equipment can help reduce false activations.

3. Cost of Installation and Maintenance: Installing and maintaining a hood suppression system can be costly, particularly for smaller restaurants. However, these costs are generally outweighed by the benefits of preventing fire damage, reducing insurance premiums, and ensuring compliance with fire codes.

4. Retrofitting Older Systems: Restaurants with older suppression systems that do not meet current standards (such as UL 300) may need to invest in upgrades or replacements to ensure compliance and effectiveness against modern fire risks.

Conclusion

Restaurant hood suppression systems are a vital component of fire safety in commercial kitchens. These systems protect lives, property, and businesses by quickly detecting and extinguishing fires before they can spread. Proper installation, regular maintenance, and compliance with fire safety standards are essential to ensure the effectiveness.

(This "Fire Safety Blogs" Published in September 2024 Edition)